Ensuring Minimal Downtime

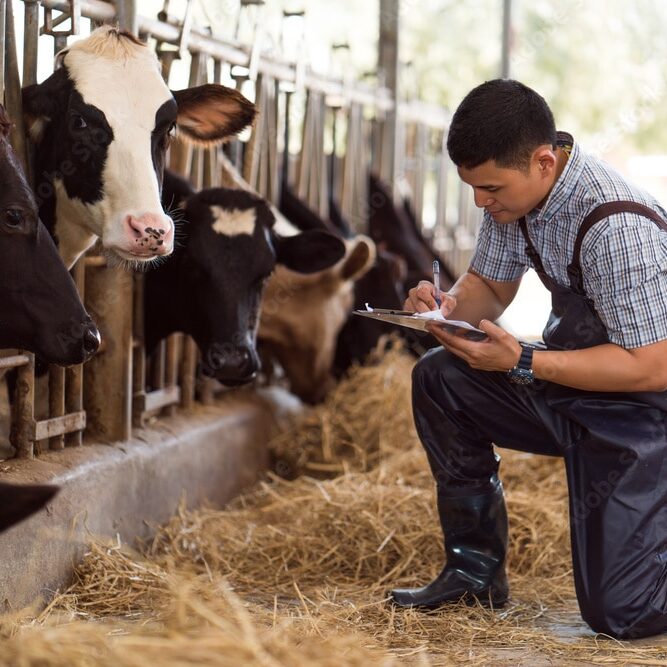

Maintaining the efficiency and reliability of milking operations is essential for dairy farms. Unsurprisingly, the question, "What specific parts should be regularly inspected and replaced to prevent downtime?" is common among farm operators. In this article, we explore key components requiring regular attention and how Electric Motor Company's products and services can assist in enhancing your farm's operational efficiency.

Essential Components for Routine Inspection

Achieving minimal downtime in milking operations starts with identifying critical components that require frequent inspection. By focusing on these areas, you can proactively address issues before they escalate into costly repairs.

Milking Systems

Vacuum Hoses and Regulators

The vacuum system is the heart of any milking operation. Regular inspections of vacuum hoses and regulators ensures they function correctly, maintaining consistent suction levels necessary for efficient milking. Replace any worn-out seals or hoses to prevent loss of vacuum pressure, which can lead to incomplete milking processes.

Milk Filters and Lines

Inspecting milk filters and lines is vital for preventing contamination and maintaining milk quality. Replace filters regularly and clean milk lines to avoid bacterial growth that could spoil milk and damage health standards.

Feed Systems

Conveyor Belts

Ensuring the smooth operation of your dairy farm's feed systems involves more than just inspecting conveyor belts for wear and tear. It's crucial to focus on the entire system, including pulleys, grooved sheaves, bearings, couplers, and gearboxes. Proper tensioning and alignment of these components are essential to the effective delivery of feed.

Barn Utilities

Ventilation Systems

Proper ventilation is necessary to maintain a healthy barn environment. Regularly inspect fans and ductwork for dust buildup and mechanical issues. Clean and replace filters and broken fan blades to ensure adequate airflow and temperature management.

Partner with Electric Motor Company for Maintenance Solutions

For optimizing your milking operations and ensuring continuous productivity, partnering with a reliable equipment supplier like Electric Motor Company is invaluable. The comprehensive range of products and services they offer supports each phase of farm equipment maintenance.

Expert Consultation and Products

Electric Motor Company provides expert guidance to help you select the right replacement parts and offers solutions tailored to dairy farms' unique needs. From state-of-the-art milking equipment to automated feeding systems, you can explore our expansive offerings.

Access to Comprehensive Spare Parts

Ensure minimal operational downtime by maintaining a well-stocked inventory of spare parts, readily available through Electric Motor Company. Their robust catalog encompasses everything from electrical components to enhanced ventilation systems, ensuring your farm always operates at peak efficiency.

Boost Your Dairy Farm Efficiency

Transform your dairy farm operations with premium equipment from Electric Motor Company. Our products are designed to keep your cows happy and your farm thriving. Explore our parts and equipment: